aerospace

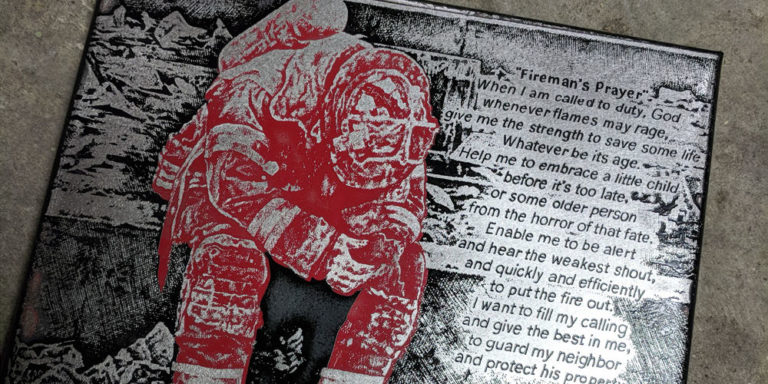

For over 50 years, the United States Department of Defense has specified Metalphoto photosensitive anodized aluminum for durable labels, nameplates, schematics and control panels installed in harsh operating environments.

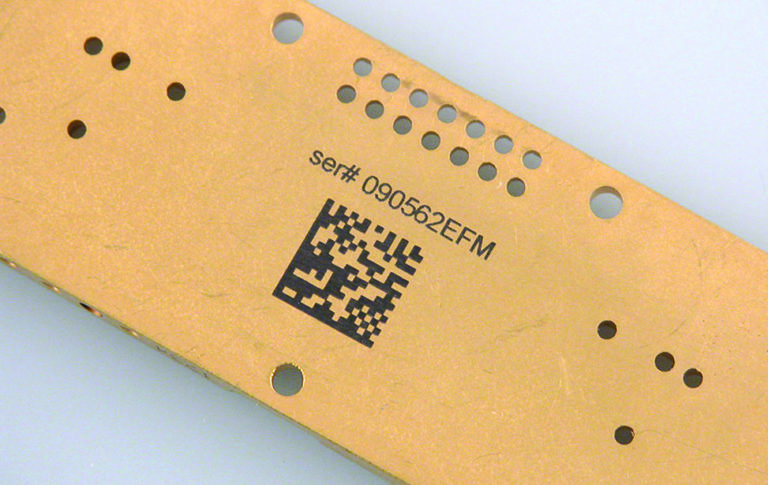

The United States Navy first adopted Metalphoto in 1958 for shipboard labels, placards and damage control signs. Since then, Metalphoto has been incorporated into several major Army weapons systems including the Abrams Tank, the Bradley Fighting Vehicle and the HMMWV. Both Marine Corps and Army Depots operate Metalphoto production facilities. All Departments utilize Metalphoto for Item Unique Identification (IUID) barcode labels as specified under MIL-STD-130.

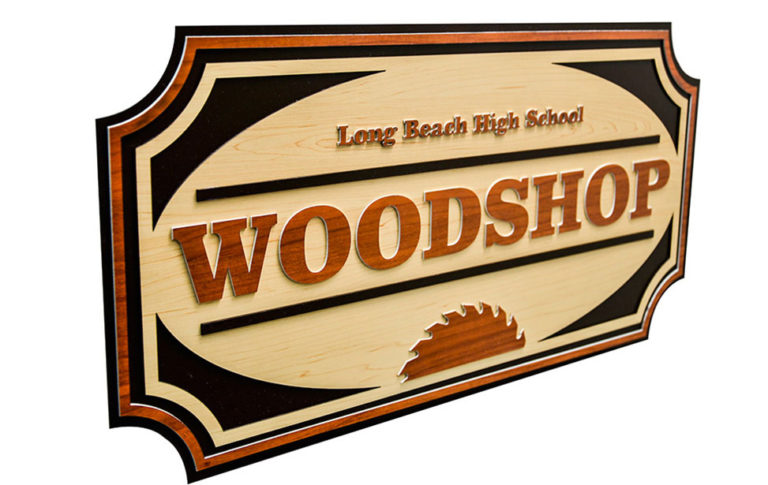

architecture

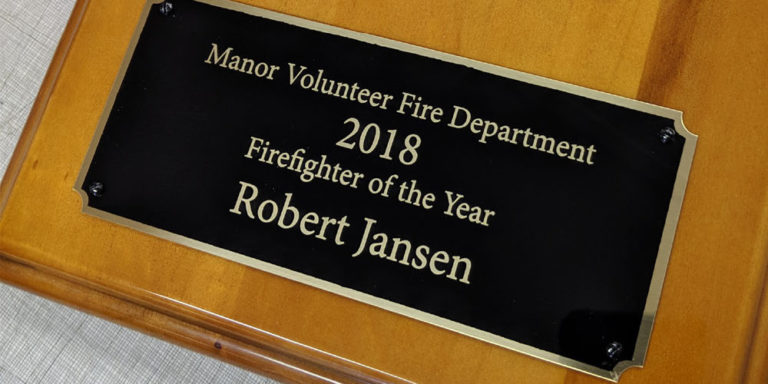

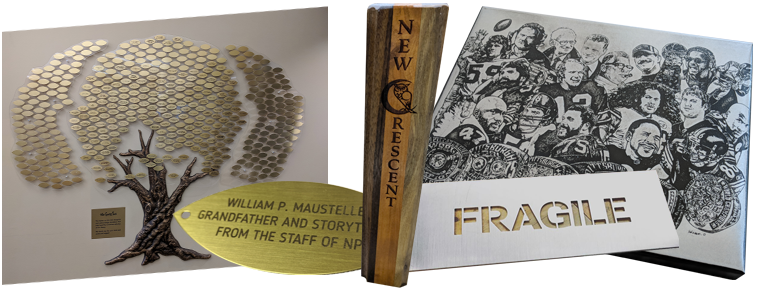

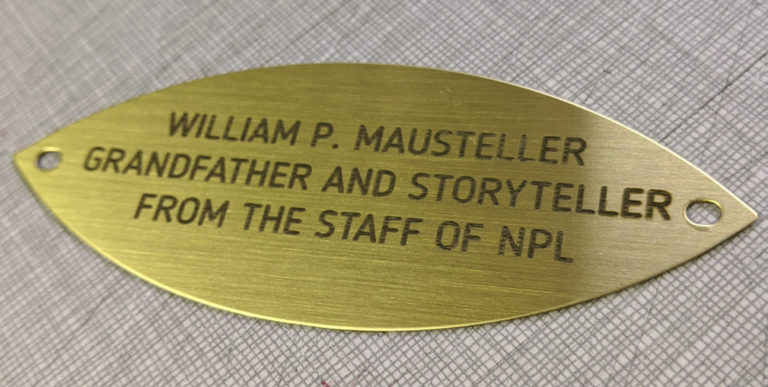

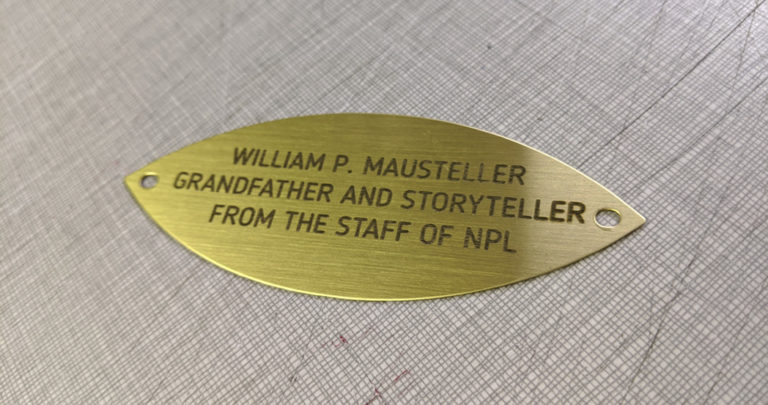

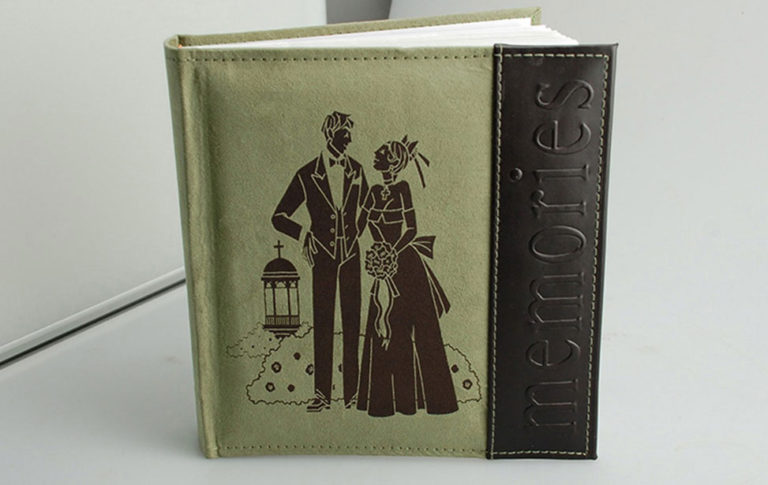

Since 1958, architects and designers have specified Metalphoto for high-value outdoor and indoor signage projects such as wayfinding signs, blueprint reproductions, building certification plaques and donor recognition plates.

Metalphoto photosensitive anodized aluminum allows you to capture rich, photographic quality images inside of metal – providing unmatched longevity and the durable, modern look of anodized aluminum. Because Metalphoto is a photographic process, its image resolution, clarity and durability are superior to printed or etched signs. The Metalphoto image is cleanable, graffiti proof and impervious to sunlight and abrasion.

AUDIO EQUIPMENT

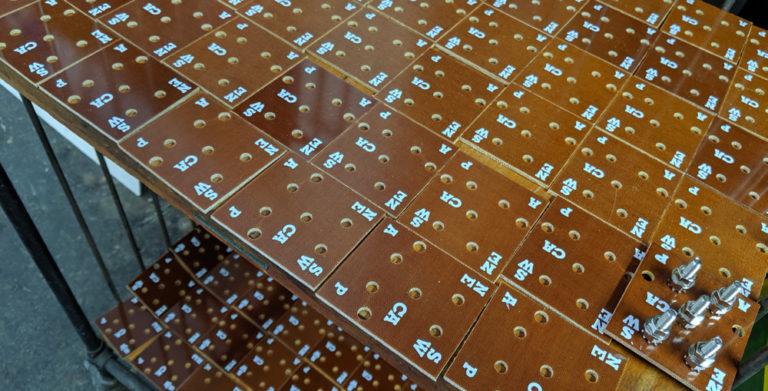

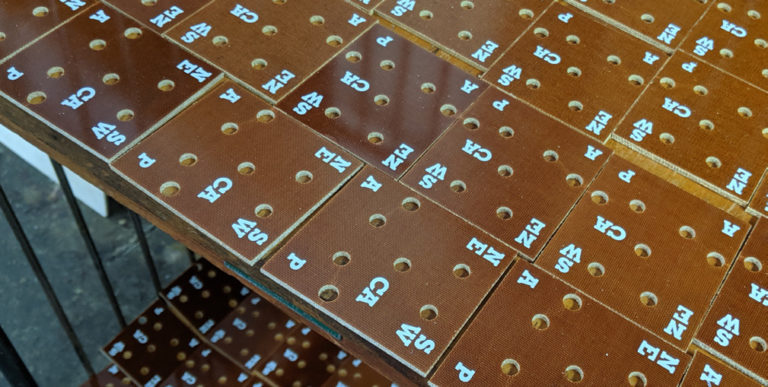

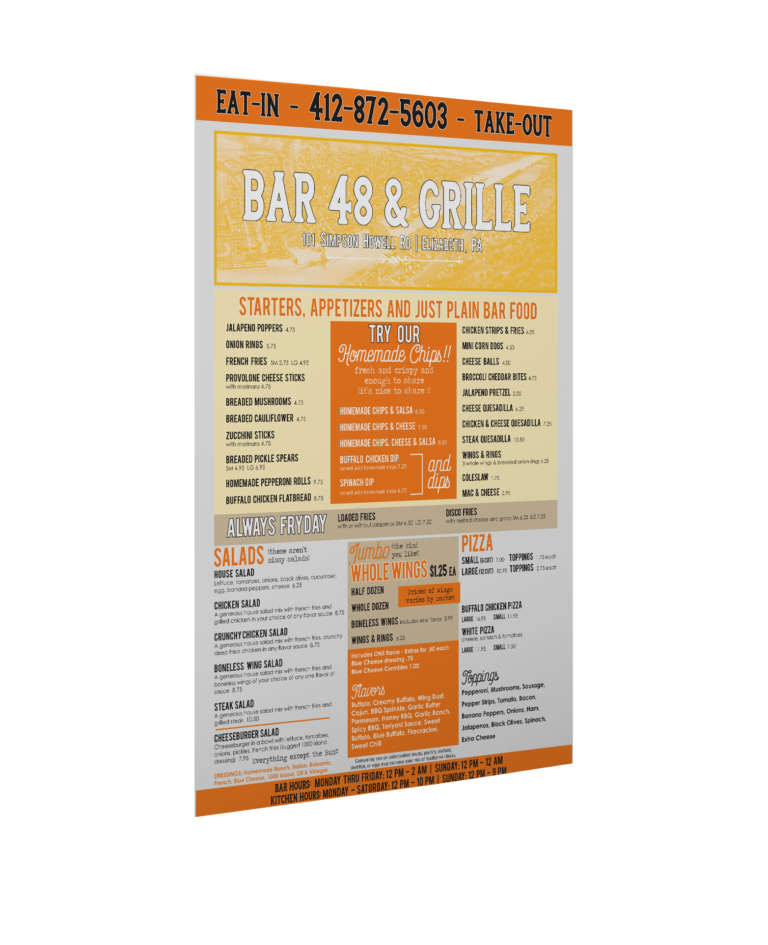

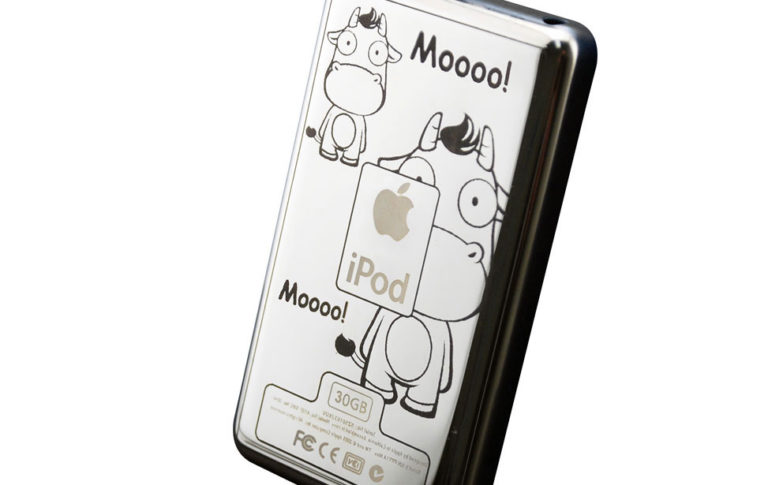

Audio: Over 30 modular synthesizer designers trust MPC to create. We supply the professional audio equipment industry their custom front panels along with custom faceplates for rack modules, MIDI equipment, mixers, amplifiers and other equipment.

- Material choices include Matte, Satin or Brushed finishes. See finishes.

- 0.063″ thickness is standard; 0.090″ and 0.125″ are also available.

- Blank panels available to fill empty case space.

- High Resolution/Detail – Our imaging processes have significantly greater resolution than screen printing.

- Industrial Durability – All images are printed beneath the anodized layer, providing unmatched durability and the smooth-to-the-touch feel of classic analogue electronic instruments.

- Accurate Fabrication – Computer Numerical Control (CNC) fabrication services available.

DEFENSE

For over 50 years, the United States Department of Defense has specified Metalphoto photosensitive anodized aluminum for durable labels, nameplates, schematics and control panels installed in harsh operating environments.

The United States Navy first adopted Metalphoto in 1958 for shipboard labels, placards and damage control signs. Since then, Metalphoto has been incorporated into several major Army weapons systems including the Abrams Tank, the Bradley Fighting Vehicle and the HMMWV. Both Marine Corps and Army Depots operate Metalphoto production facilities. All Departments utilize Metalphoto for Item Unique Identification (IUID) barcode labels as specified under MIL-STD-130.

ENERGY

For over 50 years, industrial and military engineers have specified Metalphoto photosensitive anodized aluminum for durable nameplates, barcode labels, service schematics and control panels installed in harsh operating environments. Metalphoto’s proprietary technology permanently seals a UV-stable image inside of anodized aluminum, offering the confidence of unparalleled durability, image resolution and barcode readability.

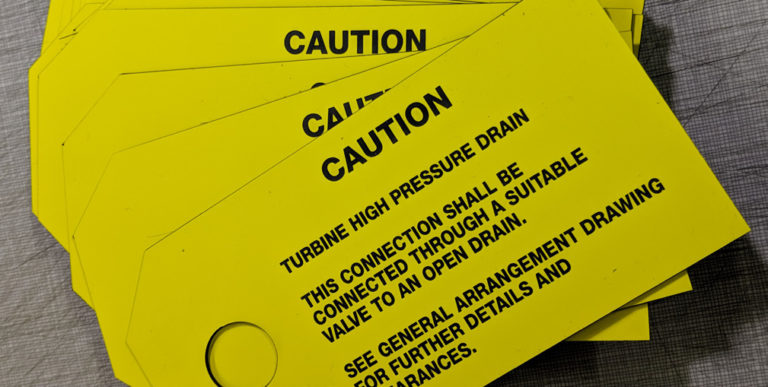

Because of its ability to withstand a range of challenging environmental conditions, Metalphoto is recommended for rating plates, inspection barcodes, maintenance schematics and other exposed identification on solar, wind and hydroelectric energy systems. Metalphoto meets an array of energy specifications including OSHA 1910.145, National Electric Code (NEC) Article 690, ANSI Z535.4 and ISO 3864. Designed for permanency, Metalphoto will not fade or need to be replaced. If replacement is desired, Metalphoto is 100% recyclable.

HEAVY EQUIPMENT

For over 50 years, industrial and military engineers have specified Metalphoto photosensitive anodized aluminum for durable nameplates, barcode labels, service schematics and control panels installed in harsh operating environments. Metalphoto’s proprietary technology permanently seals a UV-stable image inside of anodized aluminum, offering the confidence of unparalleled durability, image resolution and barcode readability.

Specified by Nordic Air (HDT Global), a leading manufacturer of military-grade mobile HVAC systems, Metalphoto nameplates, service schematics and control panels are designed to withstand installation in harsh military and industrial operating environments. Many equipment manufacturers produce Metalphoto onsite for on-demand component availability. Metalphoto is also specified for mobile flightline air-conditioning, shipboard cooling systems and mobile power generation.

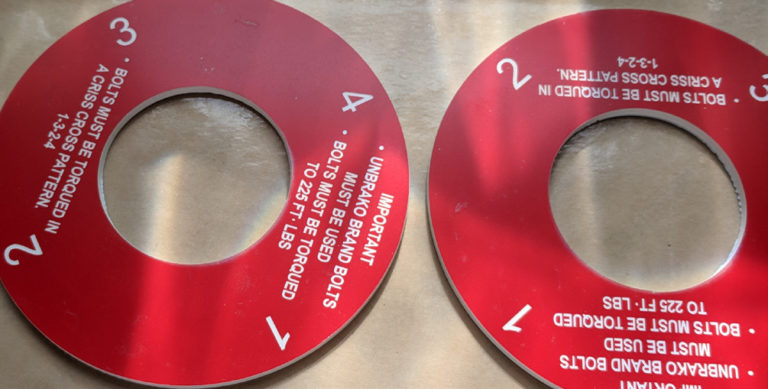

INDUSTRIAL

Industrial engines and pumps operate in sustained high-temperatures, vibration and fuel/lubricant exposure. Labeling of engines, pumps and their component parts is not only required by regulators, but imperative for the crews charged with maintaining equipment in the field. Faded, corroded or otherwise illegible nameplates and labels threaten the readability of identification items; impeding safe operation, costing companies downtime and leading to regulatory fines.

Metalphoto® photosensitive anodized aluminum has been the material of choice for engine and pump labels and nameplates for more than 50 years.

Specified by industry leaders such as Caterpillar, Cummins and Bendix, Metalphoto has proven long-term durability. That is because the Metalphoto image is sealed beneath a sapphire-hard anodized layer, providing resistance to corrosion, sunlight degradation, abrasion, extreme temperatures, and chemical exposure.

Metalphoto is used for engine and pump identification applications: engine/component labels (including barcode labels), operator faceplates/control panels, engine/pump nameplates, generator nameplates, mining equipment

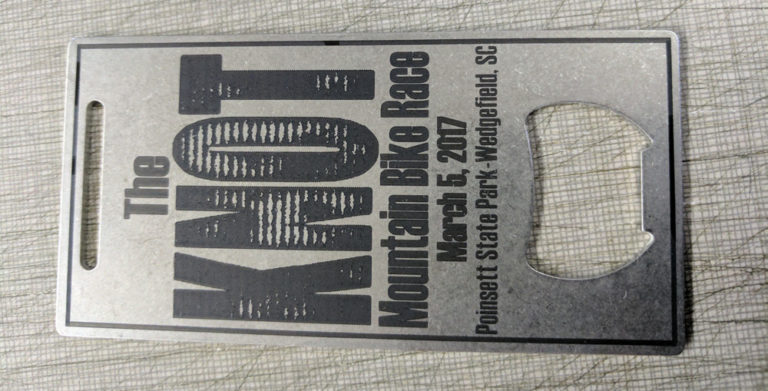

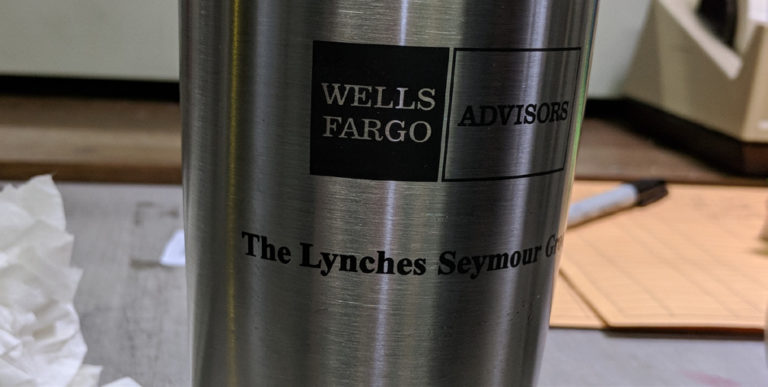

MANUFACTURING

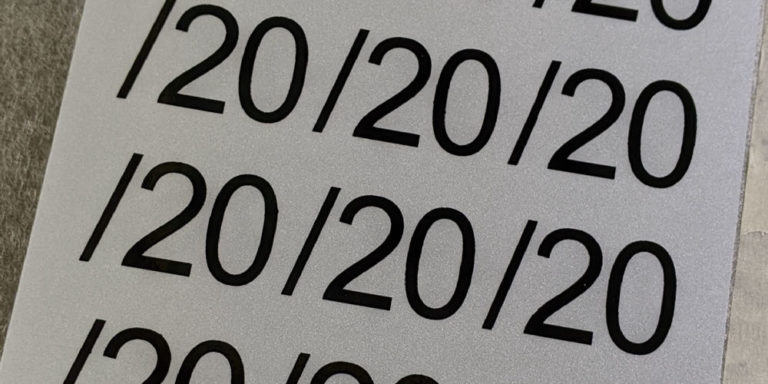

Automated manufacturing equipment – Equipment nameplates and labels must withstand abuse and represent the manufacturer’s brand image. Damaged, corroded or otherwise illegible nameplates threaten the readability of identification items; impeding safe operation, costing companies downtime and leading to regulatory fines.

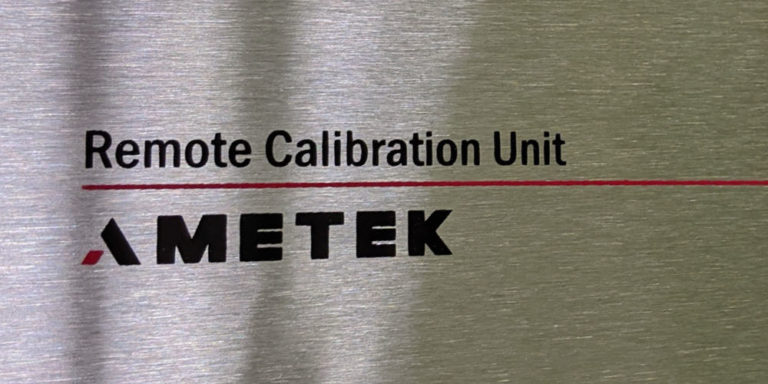

Metalphoto photosensitive anodized aluminum has been the material of choice for high-end manufacturing equipment nameplates for more than 50 years. Metalphoto image is sealed beneath a sapphire-hard anodized layer, providing resistance to corrosion, sunlight degradation, abrasion, extreme temperatures, and chemical exposure.

Metalphoto is used for manufacturing equipment identification applications such as equipment nameplates, process control component labels, test & measurement equipment nameplates, operator faceplates/control panels.

MARINE

For over 50 years, industrial and military engineers have specified Metalphoto photosensitive

anodized aluminum for durable nameplates, barcode labels, service schematics and control

panels installed in harsh operating environments. Metalphoto’s proprietary technology

permanently seals a UV-stable image inside of anodized aluminum, offering the confidence of unparalleled durability, image resolution and barcode readability.

First specified by the United States Navy in 1958, Metalphoto has been performing in demanding marine applications for over 50 years. Metalphoto’s performance in marine applications is due to its unique combination of resistance to saltwater corrosion, UV/sunlight degradation, abrasion and many solvents. Metalphoto’s industrial marine resume includes asset tags on workboats, shipping container nameplates and control panels on off-shore marine cranes.

MEDICAL

Anodized aluminum has long been a standard for sterilization containers, control panels and other identification products in the surgical field. Metalphoto photosensitive anodized aluminum improves that standard by being resistant to heat, chemicals and harsh cleaning solvents. Ideal for sterile environments, Metalphoto does not harbor bacteria or corrode after thousands of sterilization cleaning cycles.

Metalphoto complies with several medical labeling requirements including AAMI/CDV-1 ST79:2010/A2.06, a comprehensive guide to steam sterilization and sterility assurance, and the FDA Amendments Act of 2007 for the establishment of a Unique Device Identification (UDI) System.

RAILROAD

The vast majority of equipment and assets in the railroad freight and transportation industry operate outside and are routinely exposed to sunlight, abrasion and extreme temperatures, as well as corrosive elements. Items such as locomotives, passenger and freight railcars, maintenance-of-way and inspection equipment are often labeled to identify them as property, provide operating instructions and house mechanical switches for control panels, track location and lifecycle.

These labels, data plates and front panels must withstand the same conditions as the assets to which they are affixed while remaining legible after years of abuse. Faded, corroded or otherwise illegible nameplates and labels threaten readability, which may lead to unauthorized transfers or impede safe operation – even downtime or regulatory fines.

Metalphoto® photosensitive anodized aluminum is the preferred choice for panel fronts and data plates for equipment in harsh environments. The reason is simple: durability and legibility.

Metalphoto’s sapphire-hard anodized layer provides superior resistance to corrosion, sunlight degradation, abrasion, extreme temperatures, and chemical exposure. Metalphoto’s high resolution image capability allows easy usage of various type of barcodes, including linear and matrix (2D) barcodes.

TRANSPORTATION

For over 50 years, industrial and military engineers have specified Metalphoto photosensitive

anodized aluminum for durable nameplates, barcode labels, service schematics and control

panels installed in harsh operating environments. Metalphoto’s proprietary technology

permanently seals a UV-stable image inside of anodized aluminum, offering the

confidence of unparalleled durability, image resolution and barcode readability.

Hyundai Translead specifies Metalphoto nameplates for ISO 6346/BIC compliant intermodal

shipping container nameplates. Compared to traditional etched stainless steel, Metalphoto

survives longer in salt-spray, sunlight and abrasion at a fraction of the cost. Metalphoto complies with the Convention of Safe Containers Act, CSC Safety Approval Plate.

aerospace

For over 50 years, the United States Department of Defense has specified Metalphoto photosensitive anodized aluminum for durable labels, nameplates, schematics and control panels installed in harsh operating environments.

The United States Navy first adopted Metalphoto in 1958 for shipboard labels, placards and damage control signs. Since then, Metalphoto has been incorporated into several major Army weapons systems including the Abrams Tank, the Bradley Fighting Vehicle and the HMMWV. Both Marine Corps and Army Depots operate Metalphoto production facilities. All Departments utilize Metalphoto for Item Unique Identification (IUID) barcode labels as specified under MIL-STD-130.

architecture

Since 1958, architects and designers have specified Metalphoto for high-value outdoor and indoor signage projects such as wayfinding signs, blueprint reproductions, building certification plaques and donor recognition plates.

Metalphoto photosensitive anodized aluminum allows you to capture rich, photographic quality images inside of metal – providing unmatched longevity and the durable, modern look of anodized aluminum. Because Metalphoto is a photographic process, its image resolution, clarity and durability are superior to printed or etched signs. The Metalphoto image is cleanable, graffiti proof and impervious to sunlight and abrasion.

AUDIO EQUIPMENT

Audio: Over 30 modular synthesizer designers trust MPC to create. We supply the professional audio equipment industry their custom front panels along with custom faceplates for rack modules, MIDI equipment, mixers, amplifiers and other equipment.

- Material choices include Matte, Satin or Brushed finishes. See finishes.

- 0.063″ thickness is standard; 0.090″ and 0.125″ are also available.

- Blank panels available to fill empty case space.

- High Resolution/Detail – Our imaging processes have significantly greater resolution than screen printing.

- Industrial Durability – All images are printed beneath the anodized layer, providing unmatched durability and the smooth-to-the-touch feel of classic analogue electronic instruments.

- Accurate Fabrication – Computer Numerical Control (CNC) fabrication services available.

DEFENSE

For over 50 years, the United States Department of Defense has specified Metalphoto photosensitive anodized aluminum for durable labels, nameplates, schematics and control panels installed in harsh operating environments.

The United States Navy first adopted Metalphoto in 1958 for shipboard labels, placards and damage control signs. Since then, Metalphoto has been incorporated into several major Army weapons systems including the Abrams Tank, the Bradley Fighting Vehicle and the HMMWV. Both Marine Corps and Army Depots operate Metalphoto production facilities. All Departments utilize Metalphoto for Item Unique Identification (IUID) barcode labels as specified under MIL-STD-130.

ENERGY

For over 50 years, industrial and military engineers have specified Metalphoto photosensitive anodized aluminum for durable nameplates, barcode labels, service schematics and control panels installed in harsh operating environments. Metalphoto’s proprietary technology permanently seals a UV-stable image inside of anodized aluminum, offering the confidence of unparalleled durability, image resolution and barcode readability.

Because of its ability to withstand a range of challenging environmental conditions, Metalphoto is recommended for rating plates, inspection barcodes, maintenance schematics and other exposed identification on solar, wind and hydroelectric energy systems. Metalphoto meets an array of energy specifications including OSHA 1910.145, National Electric Code (NEC) Article 690, ANSI Z535.4 and ISO 3864. Designed for permanency, Metalphoto will not fade or need to be replaced. If replacement is desired, Metalphoto is 100% recyclable.

HEAVY EQUIPMENT

For over 50 years, industrial and military engineers have specified Metalphoto photosensitive anodized aluminum for durable nameplates, barcode labels, service schematics and control panels installed in harsh operating environments. Metalphoto’s proprietary technology permanently seals a UV-stable image inside of anodized aluminum, offering the confidence of unparalleled durability, image resolution and barcode readability.

Specified by Nordic Air (HDT Global), a leading manufacturer of military-grade mobile HVAC systems, Metalphoto nameplates, service schematics and control panels are designed to withstand installation in harsh military and industrial operating environments. Many equipment manufacturers produce Metalphoto onsite for on-demand component availability. Metalphoto is also specified for mobile flightline air-conditioning, shipboard cooling systems and mobile power generation.

INDUSTRIAL

Industrial engines and pumps operate in sustained high-temperatures, vibration and fuel/lubricant exposure. Labeling of engines, pumps and their component parts is not only required by regulators, but imperative for the crews charged with maintaining equipment in the field. Faded, corroded or otherwise illegible nameplates and labels threaten the readability of identification items; impeding safe operation, costing companies downtime and leading to regulatory fines.

Metalphoto® photosensitive anodized aluminum has been the material of choice for engine and pump labels and nameplates for more than 50 years.

Specified by industry leaders such as Caterpillar, Cummins and Bendix, Metalphoto has proven long-term durability. That is because the Metalphoto image is sealed beneath a sapphire-hard anodized layer, providing resistance to corrosion, sunlight degradation, abrasion, extreme temperatures, and chemical exposure.

Metalphoto is used for engine and pump identification applications: engine/component labels (including barcode labels), operator faceplates/control panels, engine/pump nameplates, generator nameplates, mining equipment

MANUFACTURING

Automated manufacturing equipment – Equipment nameplates and labels must withstand abuse and represent the manufacturer’s brand image. Damaged, corroded or otherwise illegible nameplates threaten the readability of identification items; impeding safe operation, costing companies downtime and leading to regulatory fines.

Metalphoto photosensitive anodized aluminum has been the material of choice for high-end manufacturing equipment nameplates for more than 50 years. Metalphoto image is sealed beneath a sapphire-hard anodized layer, providing resistance to corrosion, sunlight degradation, abrasion, extreme temperatures, and chemical exposure.

Metalphoto is used for manufacturing equipment identification applications such as equipment nameplates, process control component labels, test & measurement equipment nameplates, operator faceplates/control panels.

MARINE

For over 50 years, industrial and military engineers have specified Metalphoto photosensitive

anodized aluminum for durable nameplates, barcode labels, service schematics and control

panels installed in harsh operating environments. Metalphoto’s proprietary technology

permanently seals a UV-stable image inside of anodized aluminum, offering the confidence of unparalleled durability, image resolution and barcode readability.

First specified by the United States Navy in 1958, Metalphoto has been performing in demanding marine applications for over 50 years. Metalphoto’s performance in marine applications is due to its unique combination of resistance to saltwater corrosion, UV/sunlight degradation, abrasion and many solvents. Metalphoto’s industrial marine resume includes asset tags on workboats, shipping container nameplates and control panels on off-shore marine cranes.

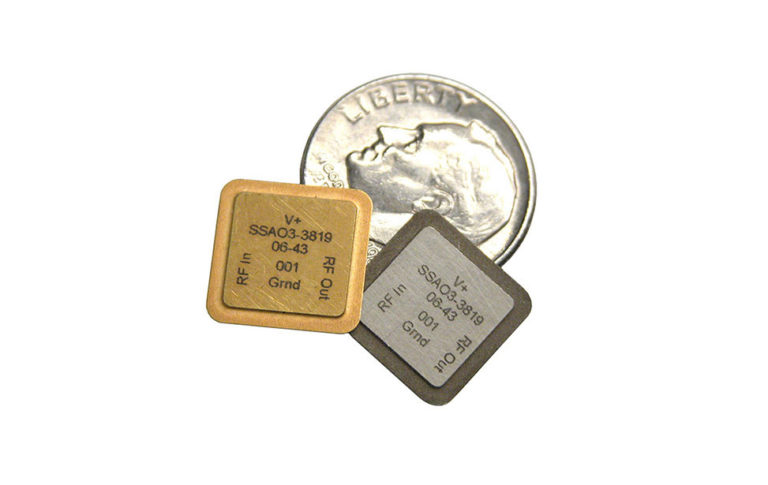

MEDICAL

Anodized aluminum has long been a standard for sterilization containers, control panels and other identification products in the surgical field. Metalphoto photosensitive anodized aluminum improves that standard by being resistant to heat, chemicals and harsh cleaning solvents. Ideal for sterile environments, Metalphoto does not harbor bacteria or corrode after thousands of sterilization cleaning cycles.

Metalphoto complies with several medical labeling requirements including AAMI/CDV-1 ST79:2010/A2.06, a comprehensive guide to steam sterilization and sterility assurance, and the FDA Amendments Act of 2007 for the establishment of a Unique Device Identification (UDI) System.

RAILROAD

The vast majority of equipment and assets in the railroad freight and transportation industry operate outside and are routinely exposed to sunlight, abrasion and extreme temperatures, as well as corrosive elements. Items such as locomotives, passenger and freight railcars, maintenance-of-way and inspection equipment are often labeled to identify them as property, provide operating instructions and house mechanical switches for control panels, track location and lifecycle.

These labels, data plates and front panels must withstand the same conditions as the assets to which they are affixed while remaining legible after years of abuse. Faded, corroded or otherwise illegible nameplates and labels threaten readability, which may lead to unauthorized transfers or impede safe operation – even downtime or regulatory fines.

Metalphoto® photosensitive anodized aluminum is the preferred choice for panel fronts and data plates for equipment in harsh environments. The reason is simple: durability and legibility.

Metalphoto’s sapphire-hard anodized layer provides superior resistance to corrosion, sunlight degradation, abrasion, extreme temperatures, and chemical exposure. Metalphoto’s high resolution image capability allows easy usage of various type of barcodes, including linear and matrix (2D) barcodes.

TRANSPORTATION

For over 50 years, industrial and military engineers have specified Metalphoto photosensitive

anodized aluminum for durable nameplates, barcode labels, service schematics and control

panels installed in harsh operating environments. Metalphoto’s proprietary technology

permanently seals a UV-stable image inside of anodized aluminum, offering the

confidence of unparalleled durability, image resolution and barcode readability.

Hyundai Translead specifies Metalphoto nameplates for ISO 6346/BIC compliant intermodal

shipping container nameplates. Compared to traditional etched stainless steel, Metalphoto

survives longer in salt-spray, sunlight and abrasion at a fraction of the cost. Metalphoto complies with the Convention of Safe Containers Act, CSC Safety Approval Plate.